If done correctly, your physical packaging can be key to improving customer experience, and even help drive down churn. It’s on your packaging that you control your brand; it’s a visual storyboard that should both excite the customer and work to your benefit, spelling out calls to actions for the customer and adding value to the unboxing experience.

Organizing, designing, and ordering custom packaging, however, can be difficult. What kind of packaging exists? How does it actually get created? What’s a good price? How many do I have to order?

These are all questions subscription business owners should be thinking about as they get ready for their first order. Below, we’ve outlined the answers to these questions (and more!) and will take you from inception to completed order on what to expect and how to maneuver during your first custom packaging order.

In addition, we’ve created this short checklist to keep you on track for completing your order:

- Packaging types

- Digital printing

- Choosing a size

- Creating a design

- Selecting the right printer for you

- Placing a custom order

Part 1: Types of Custom Packaging Available

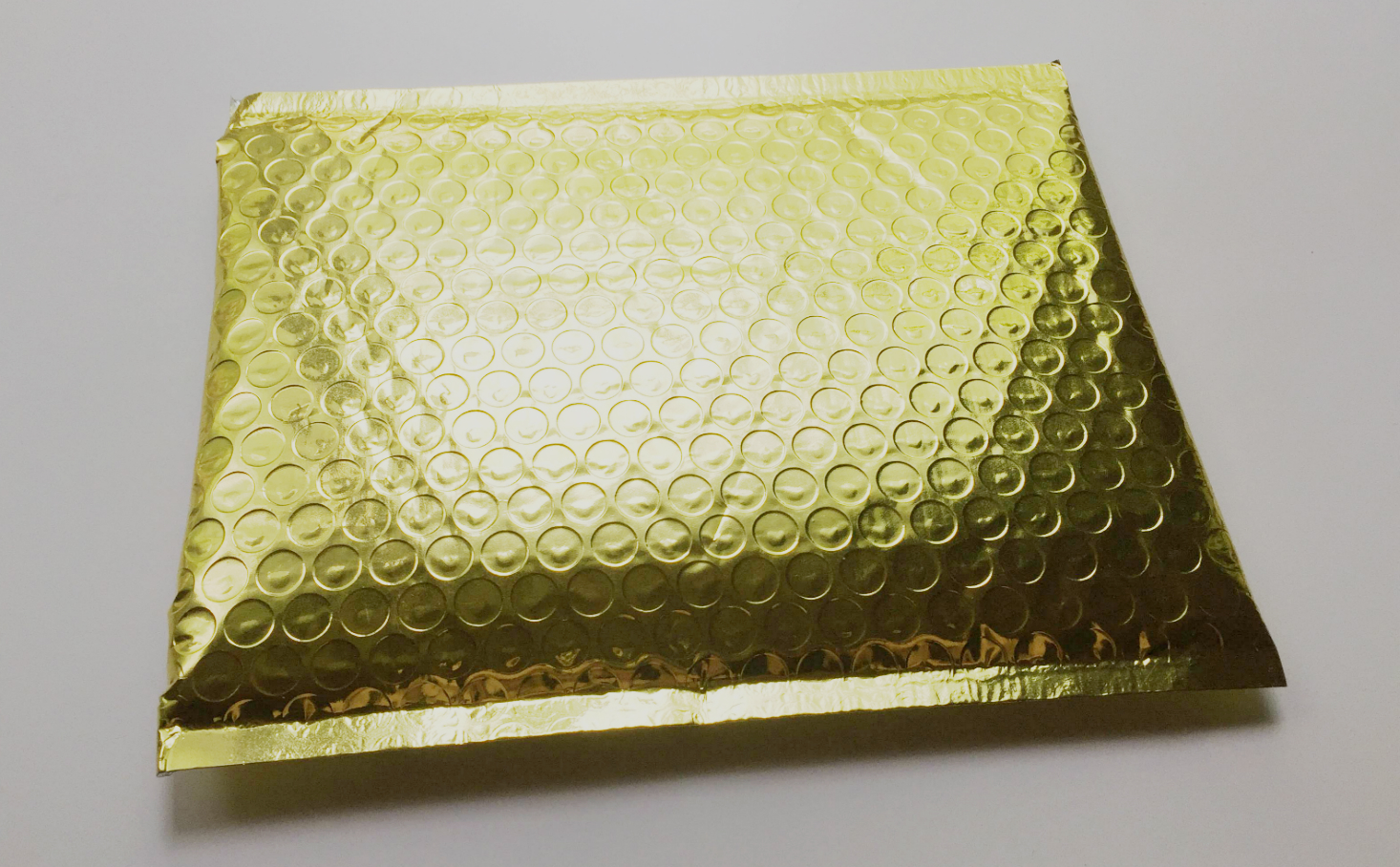

Padded/Bubble Mailers: Large envelopes built with bubble wrap (or another form of padding), utilizing a source of protection directly in the packaging design. This is ideal for smaller shipments or subscription boxes that specialize in non-fragile merchandise, such as clothing.

Mailer Boxes: Smaller-sized boxes about the size of document envelopes, but with square sides. Ideal for shipping small items like stationery or jewelry.

Custom Mailers: Regular, flexible traditional mailing envelopes without padding. Ideal for flat items like stationery.

Rigid Envelopes: These envelopes use a paperboard layer to add rigidity and durability to the package, designed to prevent any damage (such as bending) during shipping. Ideal for flat items.

When deciding on the type of packaging you’ll use, you need to think about the contents of your box, the size of each product, and how fragile they are. In the cases of large, fragile items, the traditional box mailer may be the best option available.

Questions to consider:

- What are the largest items I will include in my subscription?

- What is the most fragile item I will include in my subscription?

Part 2: The Details of Digital Printing

Once you have chosen the type of packaging you want, you can begin to think about how you want that packaging designed.

Digital printing is rapidly growing to be the most common method of printing. This is similar to the standard laserjet printer you might use at home – the machine mixes the inks and directly applies your colorful design to the box. It also allows for small minimum orders and does not require a tooling charge (for custom printing plates or dies), which means lower startup costs for you.

Interested in digital printing? Check out our partnership with BoxUp for special deals offered only to Cratejoy merchants. We break down the benefits of BoxUp and popular digital printers Packlane, Brand in Color, and Arka in Part 5 below.

You might also consider starting off with a sticker or stamp to establish your branding, if you want to keep your costs low. Many Cratejoy merchants have used custom labels or stamps before incorporating custom packaging later on. Read more in our guide.

Part 3: Choosing a Size

When debating box size, you can always take direction from existing businesses. We surveyed over 100 active subscription business owners on Cratejoy to determine the most common package sizes; see the results below.

Generally, USPS cubic shipping is the most cost-effective way to ship your subscription. Cubic pricing is not based on weight, but rather on volume. To calculate USPS cubic shipping, follow this formula:

Length x Width x Height / 1728 = Cubic Rate

(Keep in mind that the longest dimension may not exceed 18″.)

For example, if your dimensions are 10″ x 6″ x 3.75″, you end up with 225″ / 1728 = 0.13. You would then fall in the 0.2 range, as it falls over 0.1 cubic rates.

To see how this affects pricing, compare the cubic rates below:

| Cubic Feet Range (up to) |

0.10 | 0.20 | 0.30 | 0.40 | 0.50 |

|---|---|---|---|---|---|

| Zone 1 | $5.60 | $5.71 | $5.96 | $6.03 | $6.64 |

| Zone 3 | $5.77 | $5.89 | $6.18 | $6.97 | $7.82 |

| Zone 4 | $5.89 | $5.99 | $6.69 | $8.01 | $8.65 |

| Zone 5 | $6.01 | $6.13 | $8.23 | $9.57 | $10.55 |

| Zone 6 | $6.14 | $6.26 | $9.09 | $11.23 | $13.22 |

| Zone 7 | $6.42 | $6.55 | $9.87 | $12.15 | $14.97 |

| Zone 8 | $6.95 | $7.09 | $11.03 | $14.14 | $16.91 |

| Zone 9 | $9.47 | $9.66 | $15.34 | $19.82 | $24.14 |

Note: The one exception to this is if your mailer weighs under 16 oz., which would classify it as First-Class Mail and lead to better (less expensive) rates.

Why is this important? Because you can strategically size your box to decrease shipping costs.

In the earlier example, we ended up with 0.13, and by changing that size by just a few inches – to 9″ x 5″ x 3.5″ – you then end up with .09 cubic size, which is below the 0.1 cutoff. This means you can use 0.1 pricing over 0.2 pricing, and on average, save $0.13/shipment. Compared to 0.3 cubic range, you save on average $2.52/shipment.

Get a sense of how shipping costs work: Try out Cratejoy’s (free) Subscription Box Pricing calculator.

With 1000 subscribers, that’s nearly $150 of savings in shipping from 0.1 to 0.2. By 10,000 subscribers, you’re saving roughly $1500/month on shipping because of your improved pricing. Compared to 0.3 pricing, that’s $2500+ in savings with 1000 subscribers, and at 10,000 subscribers, it’s over $25,000 in savings!

When choosing your size, keep in mind that the result can have a large impact on your costs.

Part 4: Creating a Design

After you’ve chosen your packaging type and size, you’re ready to start designing!

This part of the process will likely run concurrently with the next – choosing a printer.

Many digital printing companies like BoxUp, Packlane, Brand in Color, and Arka now allow you to design your box branding online through their website, which can be faster to pull together. But if you’d like a prototype design to play with before uploading to the printer’s site, take a look at our tips.

Not confident in your design skills? Consider outsourcing this part of the project to a skilled designer. See our post on 10 services to get your subscription business off the ground for suggestions.

Because the design process can vary, we’ll offer some general tips:

- Choose your program. If using the Adobe Creative Suite, you’ll likely use Adobe InDesign for print-ready designs. You might also check out Looka to craft a basic “starter” logo; with their online logo designer, you can create designs quickly and for a low cost.

- Consider your colors. Too many colors could come off as clashing or confusing to the eye. Aim for 1-3 colors in your branding scheme to keep it simple.

- Remember calls to action (CTAs). Make sure you maximize the impact of your design to capture the customer’s excitement.

- Consider having a sample box printed. Some digital printers (see below) will send you a custom sample for free before you finalize your order. These prototypes, or “proofs,” come in a hard paperboard, not the standard corrugated cardboard, but can be used for early product shots. This will also help you decide if you like your design or if you want to change it.

Pro tip: BoxUp’s current promotion will provide you a box proof for free! Use promo code PROOF for your free sample box.

Part 5: How to Find the Right Printer

Consider the following factors when you’re searching for a digital printing company:

Location: Finding a printer that’s relatively close, like finding product manufacturers that are close, benefits you by reducing shipping and freight costs.

Price: Most digital printing companies allow you to view a cost quote as you design your order on their website. Before you start, have your specific size and order quantity in mind.

Turnaround Time: Compare and contrast the time it takes each company to print and ship your box order. (We’ve outlined turnaround times for our recommended printers below.) This timeline will impact your overall fulfillment and delivery cycle – and the time it takes for your subscribers to receive their monthly box.

So, what digital printers would Cratejoy recommend?

There are plenty of printing companies out there for subscription boxes, but we find that these three are the strongest outfits out there. Take a look!

BoxUp: As you may already know, Cratejoy has a partnership with BoxUp – and that means discounts for Cratejoy merchants. The company’s versatile range of packaging types, flexibility regarding order minimums (you can order as few as 1!), unlimited color options, and fast turnaround time persuaded us of their supreme quality.

Packlane: Like BoxUp, Packlane offers quick turnaround, near-unlimited customization and no minimum on order size. Their site also offers instant quotes, so you can estimate your packaging budget before placing an order. While Packlane offers only 3 package styles, these packages come in 3 different (sustainable) materials and custom sizes, which could add a unique spin to your box. They’ll send you a free sample box if you’re curious, too.

Brand In Color: This small business offers no restrictions on colors and the quickest turnaround time we’ve seen – 3 days from placing your order to shipping. They offer 4 box types (including pizza-style boxes!) and the capacity to print photograph-level detail clearly and brightly.

Arka: For each order you place, Arka will automatically send you a printed proof of your design (drafted by one of their designers) within 24-48 hours for approval. They won’t print any of your boxes until you approve the final design. Furthermore, Arka provides 3 board materials to customize your box and will produce any unique size you need.

Part 6: Placing an Order & Getting a Great Price

Consider box and ink quality. Recycled or sustainable packaging and ink may be more expensive but could complement your brand, depending on your niche.

Keep different types of board in mind. Not all printers will offer multiple types of box board, but some do (such as Packlane). In considering the contents of your subscription box (small or large? fragile? perishable?), ask your printer which box material they suggest for your box.

Generally, you should aim for less than $2 per box when ordering custom packaging, especially if you order over 1000 boxes at a time. As you research prices between printers, keep detailed notes on what causes changes in the price: box type, material, order volume brackets, and so on.

Note: On average, Cratejoy merchants report paying $1.61 per box. To get a sense of what’s the normal cost range per box, check out our report on Custom Subscription Box Packaging, which compiles over 100+ survey responses from merchants on pricing, quality, and satisfaction.

The Next Steps

After placing your first order, start thinking about how to increase volume and achieve better rates on future orders. Set a reminder for yourself 30 days before you run out of boxes, as well, so you can order and ship your next round of boxes. This will leave you plenty of time for shipping, packing, and making your monthly deadline!

And don’t forget: you can download our checklist for placing your first order below.

Learn More About Cratejoy’s Custom Box Program!

Check out the standard Cratejoy boxes or design your own custom boxes through the Cratejoy box program! We offer high-quality boxes, fast shipping, and special prices, only for Cratejoy sellers!